HEAT TREAMENT

-

Category: HEAT TREATMENT

HEAT TREATMENT

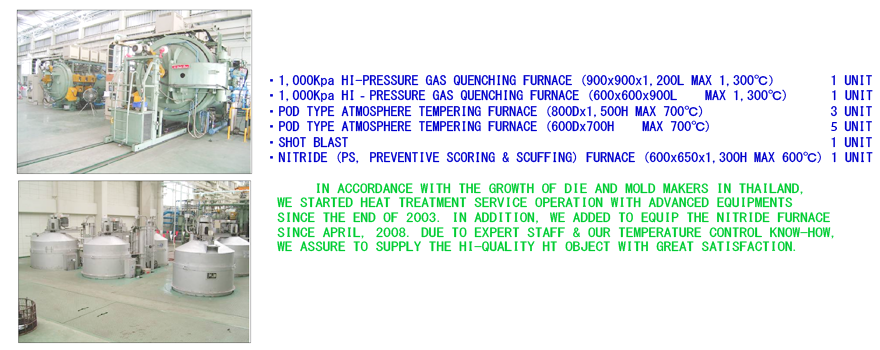

LIST OF HEAT TREATMENT EQUIPMENT

|

DEVICE |

NAME OF DEVICE |

DIMENSION |

UNIT |

MAX TEMPERATURE |

CAPACITY |

|

QUENCHING FURNACE |

1000KPa Hi-Pressure Gas Quenching Furnace V1 |

900×900×1200 |

1 |

1,300℃ |

1,200Kg/Ch |

|

1000KPa Hi-Pressure Gas Quenching Furnace V2 |

600×600×1200 |

1 |

1,300℃ |

0.600Kg/Ch |

|

|

1000KPa Hi-Pressure Gas Quenching Furnace V3 (July.'13) |

900×900×1200 |

1 |

1,300℃ |

1,200Kg/Ch |

|

|

TEMPERING FURNACE |

Pod Type Atmosphere Tempering Furnace A.B.G.I.J |

Φ800×1,500 |

5 |

700℃ |

1,500Kg/Ch |

|

Pod Type Atmosphere Tempering Furnace C.D.E.F.H |

Φ600×700 |

5 |

700℃ |

0.600Kg/Ch |

|

|

OTHERS |

Shot Blast |

Φ1,000×600H |

1 |

- |

- |

|

Quenching Water Control System |

- |

1 |

- |

1㎥/Hr |

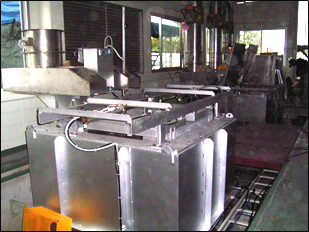

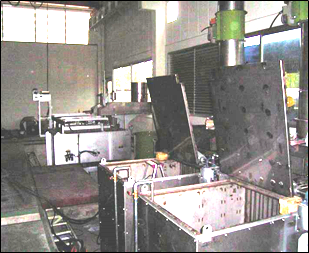

VACUUM/TEMPERING FURNACE SHOT BLAST

★Application :

| Hot/Warm Work | : | ForgingDies, Stamping Dies, Extrusion Dies, Diecasting Dies and Parts. |

| Cold Work | : | Forging Dies, Stamping Dies, Forming Dies, Plastic Mould, Metal Injection Mould. |

| Cutting Tools | : | Cutters, End-mills, Hob. |

| Rolls | : | Forming Rolls, Carving Rolls. |

| Cutters | : | Shearing/Slitting Blades, Guilotine Shears. |

| Forming Rolls | : | Rolling Dies. |

★ According to 1,000KPa quick quenching, even thick and massivediecasting dies can get high impact value.

・DHA1-A 300x300x300 210Kg

46.5HRC⇒Impact Value 24.5J/Cm2。

40.8HRC⇒Impact Value 35.5J/Cm2。

・DHA1-A 185x620x840 620Kg

44.5HRC⇒Impact 24.2J/Cm2。

★ Advanced cooling speed control system enable to prevent bothcrack and distortion after heat treatment in low level.

★ Dimentional distortion ratio of large diecasting dies (weightover 500Kg) is controlled within 0.05% in its length.

LIST OF INSPECTION EQUIPMENT

| NAME OF EQUIPMENT | UNIT |

| Rockwell Hardness Tester | 2 |

| Shore Hardness Tester | 4 |

| Brinell Hardness Tester | 1 |

| Automatic Brinell Hardness Tester | 1 |

| Ecotip Hardness Tester | 1 |

INSPECTION ROOM OVERVIEW

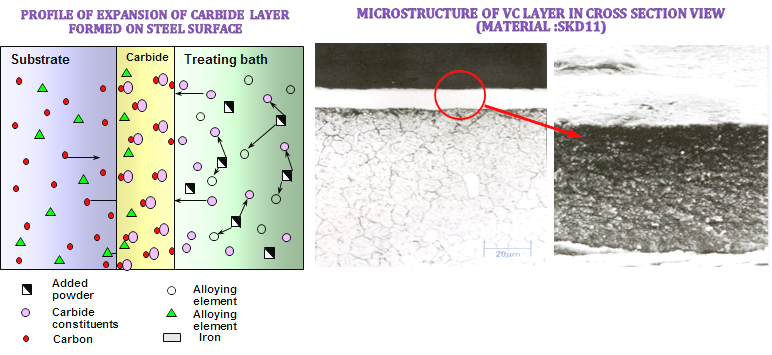

SURFACE TREATMENT (TD PROCESS)

LIST OF TD EQUIPMENT

| DEVICE | NAME OF DEVICE | DIMENSION | UNIT | MAX TEMPRERATURE | CAPACITY |

| TD FURNACE | TD(Toyota Diffusion Coating Process) Furnace | Φ400×600 | 1 | 1020℃ | 120Kg/Ch |

| OTHERS | Pre-Heating Furnace | Φ400×600 | 1 | 850℃ | - |

| Pod Type Atmosphere Tempering Furnace | Φ400×600 | 2 | 650℃ | - | |

| Cooling Unit | Φ510×810 | 1 | - | - | |

| Finishing Washing Bath | Φ510×810 | 1 | - | - |

Characterristic of TD Process (Compared with other treatment)

| TD | CVD | PVD | |

| Reaction | Thermonal & Diffusion | Thermonal reaction | Plasma |

| Layer of coating | VC | Tic,TiN,TiNC etc | Tin,TiAlN,CrN,DLC etc |

| Colour of coating | Dark gray | TiC:White Silver TiN:Gold | TiN:Gold TiAlN:Dark purple |

| Hardness 【HV】 | 3200~3700 | TiC:3300~3700 | TiN;2200~2700 |

| Thicness of layer 【μm】 | 6~10 | 7~10 | 3~5 |

| Teprerature 【℃】 | 1000~1020 | 700~1100 | 200~600 |

| Accuracy | △ | △ | ◎ |

| Adhesion | ◎ | ◎ | ○~◎ |

| Friction coefficient | ○~◎ | TiC:◎ TiN:○ | TiN:○ TiAlN:○ |

| Mirror surface | ◎ | ◎ | ○ |

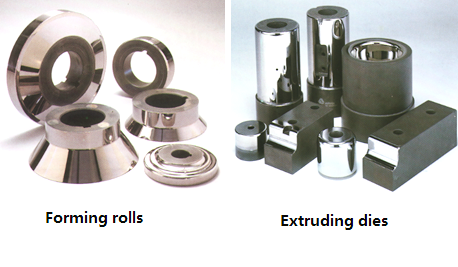

Recommended parts:

| ・Drawing punch dies | |

| ・Blanking punch dies | |

| ・Forming rolls | |

| ・Shearing cutters | |

| ・Cold forging punch dies | |

| ・Extruding dies | |

| ・Bending dies | |

| ・Swaging dies | |

| ・Core pins |

【TD Furnace】 【Tempering Furnace】

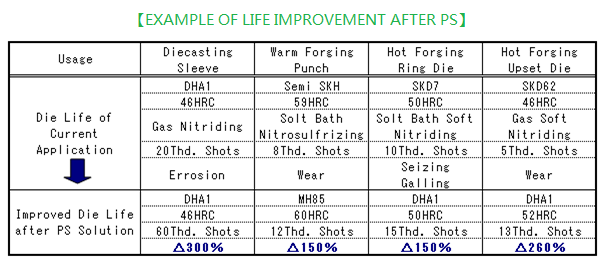

NITRIDING(PS)TREATMENT

LIST OF NITRIDING(PS)TREATMENT EQUIPMENT

| DEVICE | NAME OF DEVICE | DIMENSION | UNIT | MAX TEMPERATURE | CAPACITY |

| NITRIDING FURNACE | PS (Prevents Scoring and Scuffing) Furnace | 600×650×1,300 | 2 | 600℃ | 1,000Kg/Ch |

| PSG(PS in Gas Process) (Apr. '13) | Φ1000×1500 | 1 | 600℃ | 2,000Kg/Ch | |

| WASHING BATH | Rough Washing Bath | 992W×1,292L×1,729H | 1 | - | 25.5KW |

| Finishing Washing Bath | 992W×1,292L×1,729H | 1 | - | 25.5KW | |

| Evaporate Bath | 992W×1,292L×1,729H | 1 | - | 54.0KW |

【PS TREATMENT・NITRIDING FURNACE】 【PS TREATMENT・WASHING BATH】

★Application:

Hot/Warm WorkDies : Diecasting Dies and Parts, Forging Dies,Stamping Dies, ExtrusionDies.

Forming Tools : Rolling Dies

Others : Parts for Wear-proof

★ WEAR RESISTANCE PROPERTY IS QUITE EXCELLENT DUE TO RICHOXIDE (FECR)3O4LAYER WHICH IS STABLE THERMALLY AND IS HIGHLY ADHESIVE.

★ IT PERFORMS EXCELLENT PROPERTY BOTH IN GALLING RESISTANCEAND PREVENT-SCUFFING PROPERTY DUE TO RICH OXIDE (FECR)3O4.

★ CHANGE OF SHAPE AND DIMENSION IS VERY SMALL WITH ITS LOW PROCESS TEMPERATURE OF 520-550℃ WHICH ENABLES HARDENING SURFACE OF DC53 WITHOUT LOSING INNER HARDNESS.

★ IT PERFORMSSHORT LEAD TIME(N+1) DELIVERYACCORDING TOITS MELT-BATHTYPE TREATMENTWHICH ENABLESEASY SETTING.