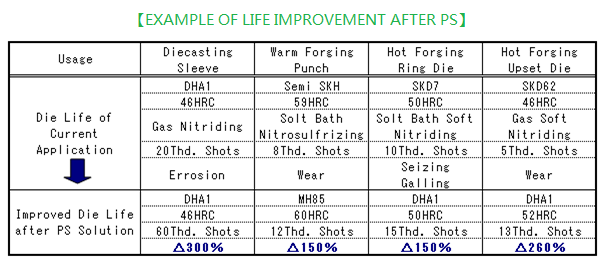

NITRIDING(PS)TREATMENT

LIST OF NITRIDING(PS)TREATMENT EQUIPMENT

| DEVICE | NAME OF DEVICE | DIMENSION | UNIT | MAX TEMPERATURE | CAPACITY |

| NITRIDING FURNACE | PS (Prevents Scoring and Scuffing) Furnace | 600×650×1,300 | 2 | 600℃ | 1,000Kg/Ch |

| PSG(PS in Gas Process) (Apr. '13) | Φ1000×1500 | 1 | 600℃ | 2,000Kg/Ch | |

| WASHING BATH | Rough Washing Bath | 992W×1,292L×1,729H | 1 | - | 25.5KW |

| Finishing Washing Bath | 992W×1,292L×1,729H | 1 | - | 25.5KW | |

| Evaporate Bath | 992W×1,292L×1,729H | 1 | - | 54.0KW |

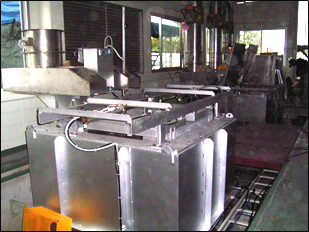

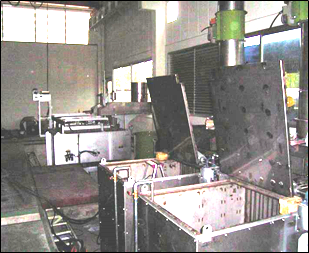

【PS TREATMENT・NITRIDING FURNACE】 【PS TREATMENT・WASHING BATH】

★Application:

Hot/Warm WorkDies : Diecasting Dies and Parts, Forging Dies,Stamping Dies, ExtrusionDies.

Forming Tools : Rolling Dies

Others : Parts for Wear-proof

★ WEAR RESISTANCE PROPERTY IS QUITE EXCELLENT DUE TO RICHOXIDE (FECR)3O4LAYER WHICH IS STABLE THERMALLY AND IS HIGHLY ADHESIVE.

★ IT PERFORMS EXCELLENT PROPERTY BOTH IN GALLING RESISTANCEAND PREVENT-SCUFFING PROPERTY DUE TO RICH OXIDE (FECR)3O4.

★ CHANGE OF SHAPE AND DIMENSION IS VERY SMALL WITH ITS LOW PROCESS TEMPERATURE OF 520-550℃ WHICH ENABLES HARDENING SURFACE OF DC53 WITHOUT LOSING INNER HARDNESS.

★ IT PERFORMSSHORT LEAD TIME(N+1) DELIVERYACCORDING TOITS MELT-BATHTYPE TREATMENTWHICH ENABLESEASY SETTING.