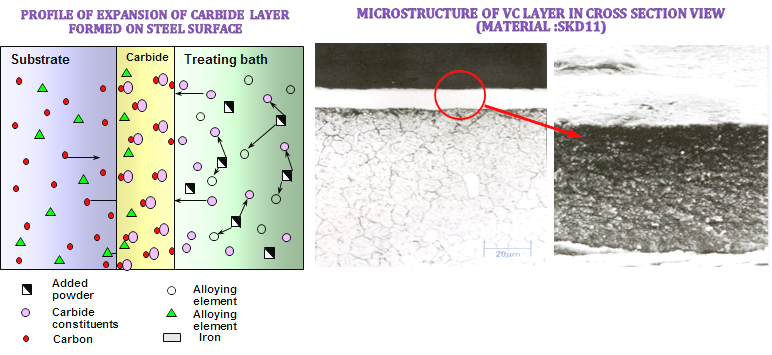

SURFACE TREATMENT (TD PROCESS)

LIST OF TD EQUIPMENT

| DEVICE | NAME OF DEVICE | DIMENSION | UNIT | MAX TEMPRERATURE | CAPACITY |

| TD FURNACE | TD(Toyota Diffusion Coating Process) Furnace | Φ400×600 | 1 | 1020℃ | 120Kg/Ch |

| OTHERS | Pre-Heating Furnace | Φ400×600 | 1 | 850℃ | - |

| Pod Type Atmosphere Tempering Furnace | Φ400×600 | 2 | 650℃ | - | |

| Cooling Unit | Φ510×810 | 1 | - | - | |

| Finishing Washing Bath | Φ510×810 | 1 | - | - |

Characterristic of TD Process (Compared with other treatment)

| TD | CVD | PVD | |

| Reaction | Thermonal & Diffusion | Thermonal reaction | Plasma |

| Layer of coating | VC | Tic,TiN,TiNC etc | Tin,TiAlN,CrN,DLC etc |

| Colour of coating | Dark gray | TiC:White Silver TiN:Gold | TiN:Gold TiAlN:Dark purple |

| Hardness 【HV】 | 3200~3700 | TiC:3300~3700 | TiN;2200~2700 |

| Thicness of layer 【μm】 | 6~10 | 7~10 | 3~5 |

| Teprerature 【℃】 | 1000~1020 | 700~1100 | 200~600 |

| Accuracy | △ | △ | ◎ |

| Adhesion | ◎ | ◎ | ○~◎ |

| Friction coefficient | ○~◎ | TiC:◎ TiN:○ | TiN:○ TiAlN:○ |

| Mirror surface | ◎ | ◎ | ○ |

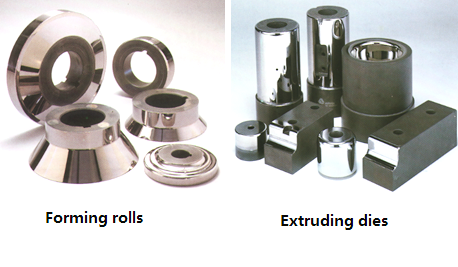

Recommended parts:

| ・Drawing punch dies | |

| ・Blanking punch dies | |

| ・Forming rolls | |

| ・Shearing cutters | |

| ・Cold forging punch dies | |

| ・Extruding dies | |

| ・Bending dies | |

| ・Swaging dies | |

| ・Core pins |

【TD Furnace】 【Tempering Furnace】